Yellow Starch Adhesive

MOQ : 1 Ton

Yellow Starch Adhesive Specification

- Hardness

- Soft (when dry)

- Tensile Strength

- High

- Surface Of Application

- Paper, Cardboard, Corrugated Sheets

- Features

- Eco-Friendly, Non-Toxic, Fast Drying

- Shelf Life

- 12 months

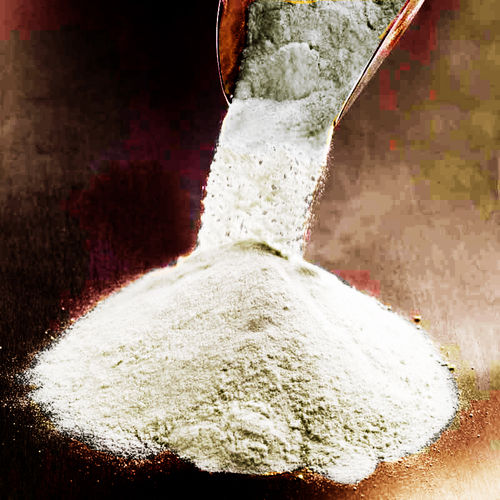

- Form

- Powder

- Material

- Starch

- Glue thickness

- Variable as per use

- Types Of Chemical

- Polysaccharide

- Storage Temperature

- Cool and Dry Place

- Adhesive Type

- Starch-Based

- Packaging Size

- 25 kg, 50 kg bags

- Holding Power

- Strong Bond

- CAS No

- 9005-25-8

- Other Names

- Dextrin Glue, Starch Gum

- Usage

- Industrial adhesive bonding

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- For Paper and Board Industries

- Color

- Yellow

- Physical State

- Powder

Yellow Starch Adhesive Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 35 Tons tons Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- STANDARD PACKING

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia, Central America

- Main Domestic Market

- All India

About Yellow Starch Adhesive

Our Yellow Starch Adhesives are popular for their consistent viscosity. Their well powdered and impurity free formulation earns them high appreciation in the global market. Our composed Yellow Starch Adhesives are used widely in paper as well as herbal industries. They are also suitable to be used in the composition of colors. The adhesives easily mix with water and need no heating prior to their application. Their sealed packaging keeps their quality and purity intact before their usage by clients.

Reliable Adhesive Solution for the Paper Industry

Yellow Starch Adhesive delivers strong, fast-setting bonds for paper and board manufacturing. Its neutral pH ensures compatibility with sensitive materials, while its non-toxic and eco-friendly formulation supports sustainable production. The powder dissolves effortlessly in cold water, and viscosity can be precisely adjusted according to application requirements. Ideal for consistent performance and reliable results, it is the preferred choice for high-volume industrial adhesive needs.

Convenient Application and Quick Drying

Designed for maximum efficiency, the adhesive sets in just 5 to 15 minutes, depending on layer thickness. Its recommended 1:3 powder-to-water ratio guarantees ease of use and consistent results, while storage requirements are minimaljust keep the packaging tightly closed in a cool, dry space. The powder form allows operators to prepare only as much adhesive as needed, minimizing waste and maximizing shelf life.

FAQs of Yellow Starch Adhesive:

Q: How is Yellow Starch Adhesive applied in industrial settings?

A: To use Yellow Starch Adhesive, mix 1 part of the powder with 3 parts cold water, stirring until fully dissolved. Adjust viscosity if needed by varying water levels. Apply the adhesive to surfaces such as paper, cardboard, or corrugated sheets, ensuring an even coat. The fast-drying formula sets within 5 to 15 minutes, depending on thickness.Q: What are the key benefits of this starch-based adhesive compared to synthetic alternatives?

A: Yellow Starch Adhesive is non-toxic, eco-friendly, and odorless, offering a safe working environment. Its strong bonding capability, fast drying time, and adjustable viscosity provide versatility for various industrial tasks. Additionally, its natural composition makes it suitable for applications where sustainability and safety are priorities.Q: When should I use Yellow Starch Adhesive for maximum effectiveness?

A: This adhesive performs best in the paper, board, and corrugated sheet industries where reliable, quick-setting bonds are required. Use it during laminating, packaging, or bonding tasks to achieve high tensile strength and smooth application. For optimal results, ensure surfaces are clean and the adhesive is freshly mixed.Q: Where should Yellow Starch Adhesive be stored to maintain shelf life?

A: Store the adhesive powder in a cool, dry place, tightly sealed in its original packaging. Lower humidity and moderate temperatures will maintain a shelf life of up to 12 months and prevent clumping or loss of efficacy.Q: What makes the adhesive suitable for paper and cardboard applications?

A: The adhesives high purity (99%), neutral pH, strong holding power, and ability to form soft yet durable bonds after drying make it ideal for delicate substrates like paper and cardboard. It does not stain or emit odors, ensuring the quality of finished products.Q: How do I adjust the viscosity of the adhesive for different applications?

A: Viscosity can be easily modified by altering the amount of water added to the powder. For thicker glue, reduce the water ratio; for thinner coatings, increase the liquid proportion. This flexibility allows customization for various equipment and bonding requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Spirally Wound Papers Adhesive Category

Industrial Starch Adhesive

Price Range 47000.00 - 52000.00 INR

Minimum Order Quantity : 1 Ton

Adhesive Type : Other, Water based

Grade : Industrial Grade

Other Names : Starch Glue, Dextrin Adhesive

Tube Starch Adhesive Gum Powder

Price 40 INR / Metric Ton

Minimum Order Quantity : 1 Kilograms

Adhesive Type : Other

Grade : Industrial

Other Names : Dextrin Adhesive

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS